Zeolite Filter Factory – air dry Ceramic Clay powder for sale – Xinzheng Cheng

Zeolite Filter Factory – air dry Ceramic Clay powder for sale – Xinzheng Cheng Detail:

Introduction of clay

Clay is a sticky soil with few sand particles, and it has good plasticity only when water cannot pass through it easily.

Common clay is formed by the weathering of silicate minerals on the surface of the earth. Generally, it is weathered in situ. The particles are larger and the composition is close to the original stone, which is called primary clay or primary clay. The main ingredients of this kind of clay are silica and alumina, which are white in color and refractory, and are the main raw materials for the preparation of porcelain clay.

Clay is generally formed by weathering of aluminosilicate minerals on the earth’s surface. But some diagenesis can also produce clay. The appearance of clay during these processes can be used as an indicator of the progress of diagenesis.

Clay is an important mineral raw material. It is composed of a variety of hydrated silicates and a certain amount of alumina, alkali metal oxides and alkaline earth metal oxides, and contains impurities such as quartz, feldspar, mica, sulfate, sulfide, and carbonate.

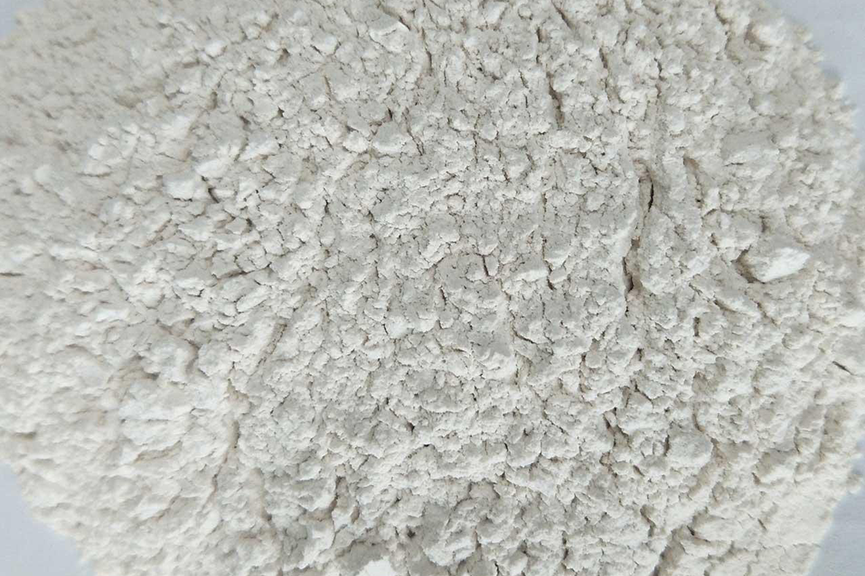

Clay minerals are small, often within the colloidal size range, in crystalline or non-crystalline form, most of which are flake-shaped, and a few are tubular or rod-shaped.

Clay minerals are plastic after being moistened with water, can be deformed under low pressure and can remain intact for a long time, and have a large specific surface area. The particles are negatively charged, so they have good physical adsorption and surface chemical activity, and are compatible with other cations. Ability to exchange.

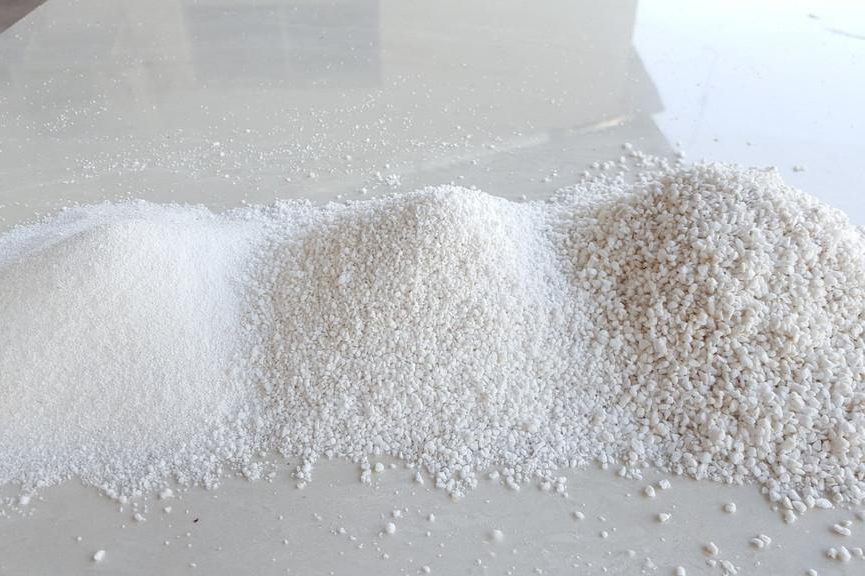

Type of clay

According to the nature and use, it can be divided into ceramic clay, refractory clay, brick clay and cement clay. Hard clay is often in the form of blocks or slabs. It is generally not immersed in water and has a high refractoriness. It is the main raw material for refractory products. The hard clay in the refractory clay is used to make blast furnace refractories, lining bricks and plug bricks for iron smelting furnaces, hot blast stoves, and steel drums. In the ceramic industry, hard clay and semi-hard clay can be used as raw materials for the manufacture of daily-use ceramics, architectural ceramics and industrial ceramics.

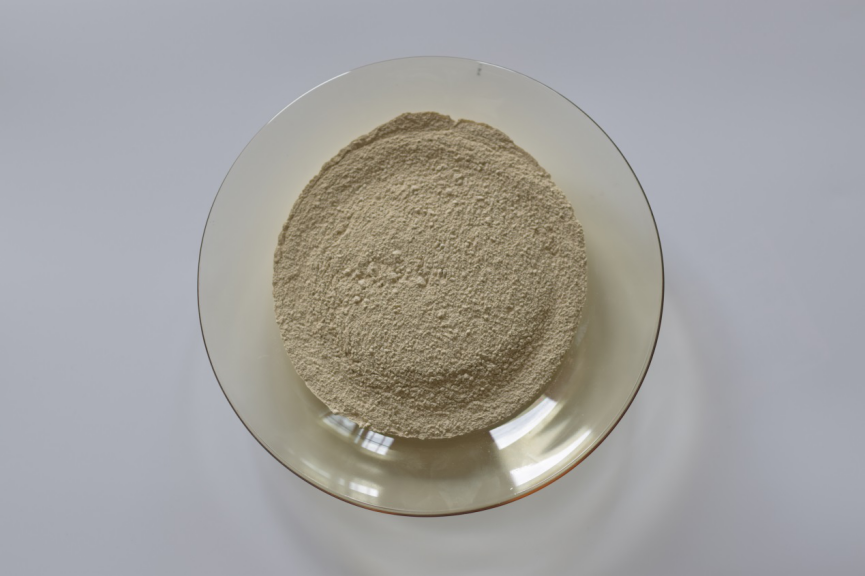

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for Zeolite Filter Factory – air dry Ceramic Clay powder for sale – Xinzheng Cheng , The product will supply to all over the world, such as: Georgia, Zimbabwe, Belize, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!