HGM Hollow Glass Microspheres thermal insulation manufacturers

Introduction of hollow glass microspheres

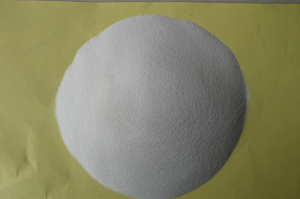

The hollow glass microspheres are off-white in appearance, which is a loose powder material with good fluidity. The characteristics are: sound insulation, flame retardation, good electrical insulation, low density, low oil absorption, and high strength. It is widely used in printing inks, adhesives, engineering plastics, modified rubber, and electrical insulation parts. Because of its stable performance, good weather resistance, and low price, it has been widely used.

The main components of the hollow glass microspheres are silicon dioxide-SiO2 and aluminum oxide-Al2O3 after being fired and sorted at a high temperature of 1400°C. The diameter of hollow glass microspheres is between 5 and 1000 microns.

Application of hollow glass microspheres

1.Light weight and large volume

The density of hollow glass beads is about one tenth of the density of traditional filler particles. After filling, it can greatly reduce the basis weight of the product, replace and save more production resins, and reduce product costs.

2.High dispersion, good liquidity

Because hollow glass beads are tiny spheres, they have better fluidity in liquid resin than flake, needle or irregularly shaped fillers, so they have excellent mold filling performance. What's more important is that the hollow glass microspheres are isotropic, so they won't have the disadvantage of inconsistent shrinkage of different parts due to orientation, and ensure the dimensional stability of the product without warping.

3.Heat insulation, sound insulation, insulation, low water absorption

The inside of the hollow glass beads is a thin gas, so it has the characteristics of sound insulation and heat insulation, and is an excellent filler for various heat preservation and sound insulation products. The thermal insulation properties of hollow glass microspheres can also be used to protect the product from the thermal shock caused by the alternation between rapid heating and rapid cooling conditions. The high resistivity and low water absorption make it widely used in the processing and production of cable insulation materials.

4.Low oil absorption

The particles of the sphere determine its smallest specific surface area and low oil absorption. During use, the amount of resin can be greatly reduced. Even under the premise of high addition, the viscosity will not increase much, which greatly improves the production and operating conditions. Increase production efficiency by 10%-20%.

hollow glass microspheres is filler and lightening agent in paint coatings, rubber, modified plastics, glass fiber reinforced plastics, artificial stone, putty and other industries; oil and gas field mining industries can produce high-strength low-density cement slurry and low-density by using its high compressive and low-density properties Drilling fluid.