Gardening Expanded Perlite Factories – Lightweight plastering plaster mortar mix for builders – Xinzheng Cheng

Gardening Expanded Perlite Factories – Lightweight plastering plaster mortar mix for builders – Xinzheng Cheng Detail:

Lightweight plastering plaster mortar Introduction

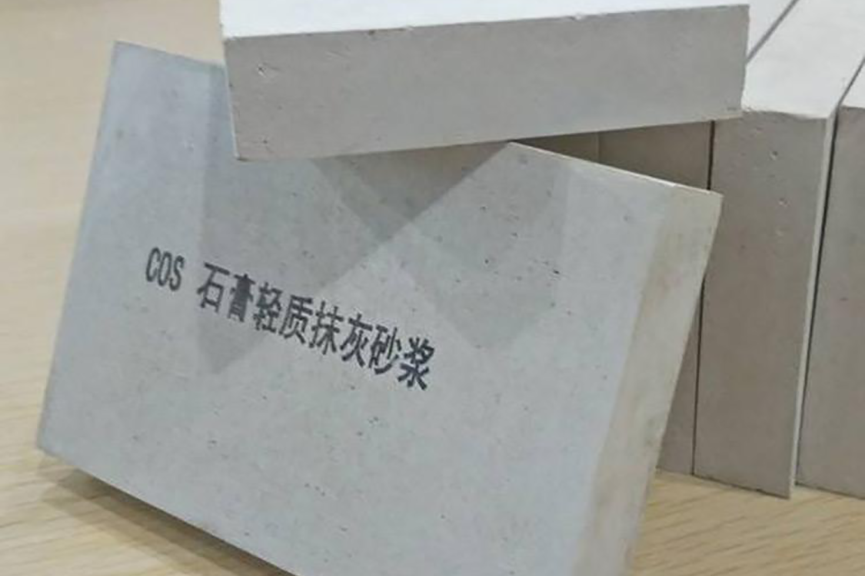

Lightweight plastering plaster mortar is a dry powder material that our company uses high-quality calcined desulfurized gypsum powder, vitrified microbeads and imported admixtures to mix in a certain proportion. This product is specially used for leveling indoor walls and ceilings of high-end construction projects. It is a new, environmentally friendly and economical product promoted by the country instead of cement mortar. It not only has the strength of cement, but is also healthier and more environmentally friendly than cement, durable and durable, with strong adhesion, not easy to pulverize, cracking, hollowing, and not falling. Powder and other advantages, easy to use and cost-saving. In terms of unit price, plastering gypsum mortar is more expensive than cement mortar, but plastering gypsum mortar has many advantages. Taken together, the plastering cost per square meter of plastering gypsum mortar is lower than cement mortar.

Features of Lightweight plastering plaster mortar

Adjust air humidity

When the external humidity is higher than the relative humidity of the plastering gypsum, because the external vapor pressure is higher than its saturated vapor pressure, the internal behavior is caused to adsorb moisture, thereby delaying the increase in humidity; when the external humidity is lower than the corresponding humidity of the plastering gypsum, The external vapor pressure is lower than its saturated vapor pressure, which promotes the evaporation of internal water molecules, therefore, it can play a role in regulating and controlling humidity.

Building load is effectively reduced

The bulk density of plastering plaster is 750-950kg/m³; only half of the traditional cement plastering mortar 1800-2000kg/m³. For example, if a building (two units with 20 floors) is replaced by plastering plaster instead of traditional cement mortar, the whole building Will reduce the load by 550 tons.

Flame retardant

The molecular weight of Lightweight plastering plaster mortar is 172, and the molecular weight of water is 18. When a house of 100 square meters encounters a fire, when the temperature reaches 110°C or higher, the dihydrate gypsum will quickly release crystal water and turn into hemihydrate gypsum and then further turn into non-freezing gypsum. Hydrogypsum can release 560kg of water. The water can absorb a lot of heat during the evaporation process, which can effectively prevent the rapid rise of the room temperature and improve the chance of escape.

Sound absorption and impact resistance

During the setting process of plaster plaster, there are tiny voids inside, so it can attenuate sound pressure, prevent sound energy projection, can convert sound energy into heat energy, so it has good sound insulation performance. Due to the condensed porous structure, it can effectively absorb impact energy, so it will not crack and fall off when subjected to impact.

Insulation

The thermal conductivity of plastering plaster is 0.17W/MK, and the thermal conductivity of traditional cement plastering mortar is 0.93W/MK, so the thermal conductivity of plastering plaster is 20% of that of traditional cement plastering mortar, which has a certain thermal insulation effect. , Can reduce the energy consumption of the building.

Workers’ construction labor intensity and efficiency

Since the bulk density of plastering plaster is only about half of that of traditional cement plastering mortar, workers only need to pay half of the physical strength for the same area of construction, so the labor intensity of workers will be greatly reduced, and the construction efficiency will also be improved. In addition, no curing is required after plastering and plastering, and the hydration setting time is short, and the next process can be constructed after 24 hours.

Eco Friendly

After the gypsum is harmlessly treated, it does not contain soluble pollutants. The inorganic cementing materials and additives used are all environmentally friendly products. The light plastering gypsum made does not release harmful substances such as formaldehyde, which is environmentally friendly and safe.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Gardening Expanded Perlite Factories – Lightweight plastering plaster mortar mix for builders – Xinzheng Cheng , The product will supply to all over the world, such as: Greece, Bahamas, Germany, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.