China High quality Zeo Natural Zeolite Powder Factories – Powder metallurgy hollow fly ash cenosphere particles supplies – Xinzheng Cheng

China High quality Zeo Natural Zeolite Powder Factories – Powder metallurgy hollow fly ash cenosphere particles supplies – Xinzheng Cheng Detail:

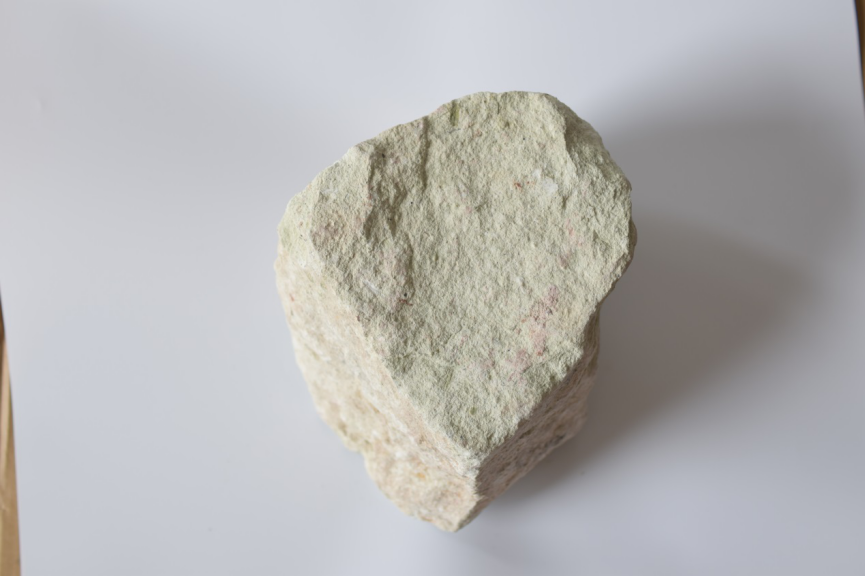

Introduction of fly ash cenosphere

fly ash cenosphere is a kind of fly ash hollow ball that can float on the water surface. fly ash cenosphere is off-white, with thin and hollow walls, very light weight, 160-400 kg/m3, particle size of about 0.1-0.5 mm, and the surface is closed and smooth. Low thermal conductivity, refractoriness ≥1610℃, it is an excellent thermal insulation refractory material, widely used in the production of lightweight castables and oil drilling. The chemical composition of fly ash cenosphere is mainly silica and aluminum oxide. It has many characteristics such as fine particles, hollow, light weight, high strength, wear resistance, high temperature resistance, thermal insulation, insulation and flame retardant.

Fly ash cenosphere have the following advantages

1. The amount of resin is small / the potential for addition is great: because in any shape, the spherical shape has the smallest specific surface area, and the fly ash cenosphere require the least amount of resin.

2. Low viscosity/improved fluidity: Unlike irregular-shaped particles,fly ash cenosphere can easily roll between each other. This makes the system using fly ash cenosphere have lower viscosity and better fluidity. Moreover, the sprayability of the system has also been improved;

3. Hardness/abrasion resistance: fly ash cenosphere is a kind of high strength and hard microspheres, which can enhance the hardness, scrubbing resistance and abrasion resistance of the coating;

4. Excellent heat insulation effect: due to the hollow sphere structure of fly ash cenosphere, it has excellent heat insulation effect when filled in paint;

5. Inertness: fly ash cenosphere is composed of inert ingredients, so they have excellent durability, weather resistance, corrosion resistance and chemical resistance;

6. Opacity: The hollow spherical shape of the fly ash cenosphere slows and scatters light, which results in an increase in the hiding power of the paint;

7. Dispersibility: The dispersion of fly ash cenosphere is the same as mineral fillers. Due to the thick wall and high compressive strength of fly ash cenosphere, it can withstand the processing of all kinds of mixers, extruders and molding machines;

Other usage of fly ash cenosphere

1. Refractory insulation materials; such as lightweight sintered refractory bricks, lightweight non-fired refractory bricks, casting insulation risers, pipe insulation shells, fire-proof insulation coatings, insulation pastes, composite insulation dry powder, lightweight insulation and wear-resistant glass fiber reinforced plastics,

2. Petroleum industry; oilfield cementing to reduce leakage, pipeline anticorrosion and insulation, subsea oilfields, floating devices, oil well drilling mud reducers, oil and gas pipelines, etc.

3. Insulating materials; plastic activation fillers, high temperature and high pressure insulators, etc.,

4. Aerospace and space development; surface composite materials for satellites, rockets, and spacecraft, satellite fire protection layer, marine equipment, ships, deep-sea submarines, etc.;

5. Powder metallurgy: It is mixed with light metals such as aluminum and magnesium to make foam metal. Compared with the base alloy, this composite material has the characteristics of low density, high specific strength and high rigidity, good damping performance and wear resistance.

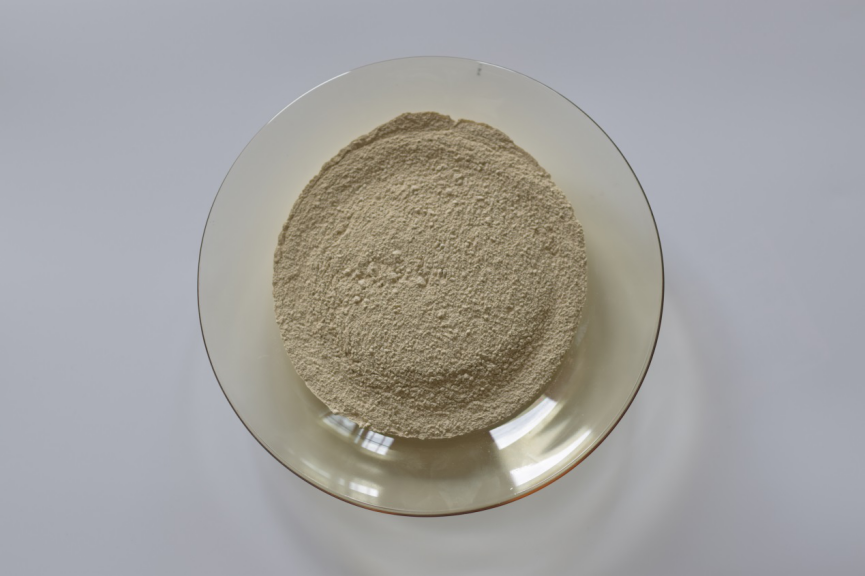

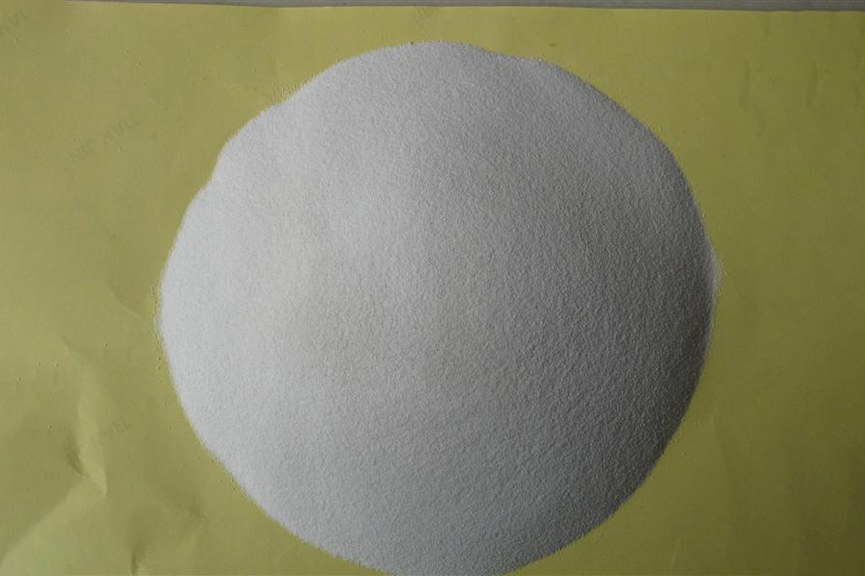

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of China High quality Zeo Natural Zeolite Powder Factories – Powder metallurgy hollow fly ash cenosphere particles supplies – Xinzheng Cheng , The product will supply to all over the world, such as: Thailand, Mali, Afghanistan, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.