China High quality Foam Board Insulation Waterproof Suppliers – 8-16mm ceramic ceramsite for plants – Xinzheng Cheng

China High quality Foam Board Insulation Waterproof Suppliers – 8-16mm ceramic ceramsite for plants – Xinzheng Cheng Detail:

Introduction of Ceramsite

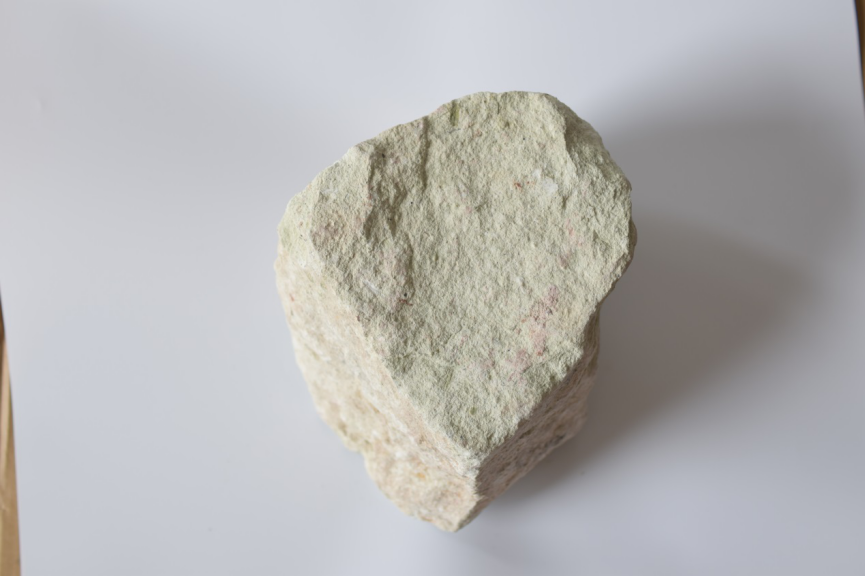

Ceramsite, as the name suggests, is ceramic particles. Most of the appearance features of ceramsite are round or oval spheres, but there are also some imitation crushed stone ceramsites that are not round or elliptical spheres, but are irregularly crushed.

The shape of the ceramsite varies depending on the process. Its surface is a hard shell, which is ceramic or enamel, which has the effect of water and gas retention and gives the ceramsite high strength.

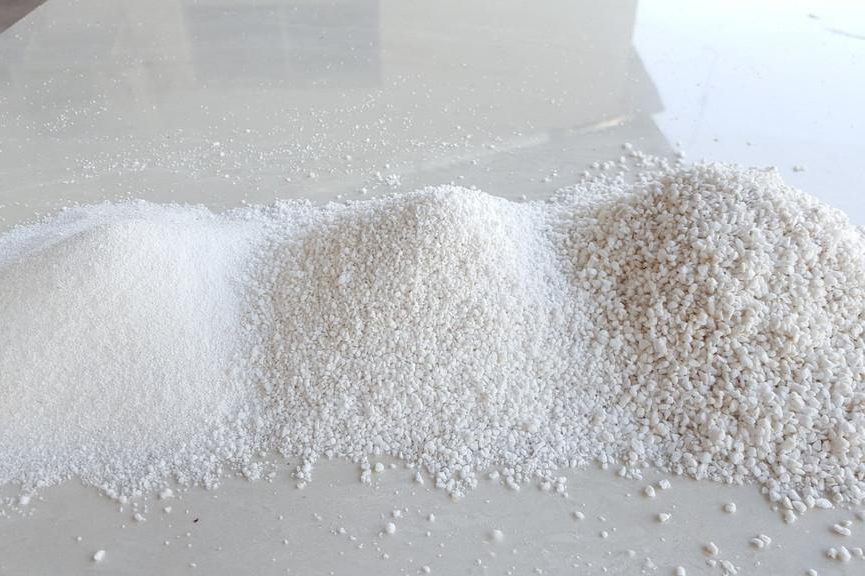

The particle size of ceramsite is generally 5-20mm, and the largest particle size is 25mm. Ceramsite is generally used to replace gravel and pebbles in concrete.

Lightness is the most important point of the many excellent properties of ceramsite, and it is also the main reason why it can replace heavy sand. The internal structure of ceramsite is characterized by dense honeycomb-like micropores. These pores are closed, not connected. It is formed by the gas being wrapped into the shell, which is the main reason for the light weight of ceramsite.

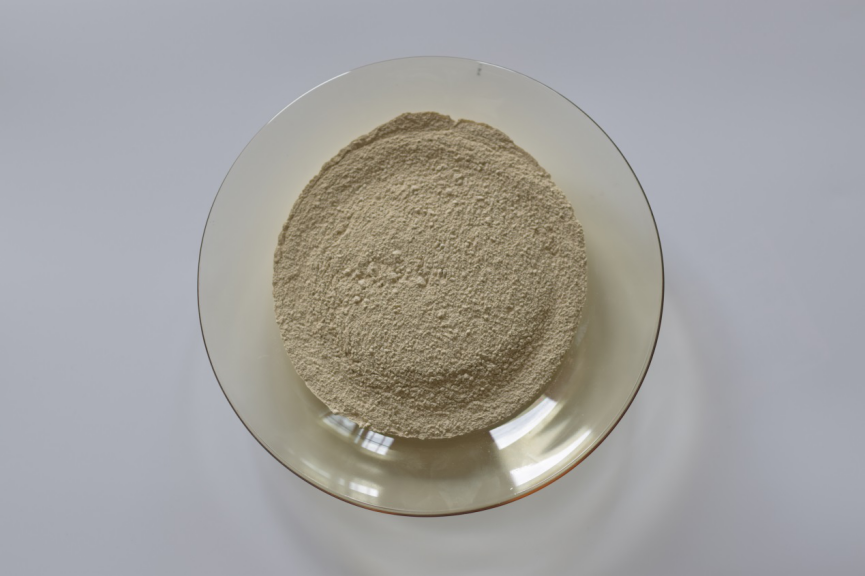

The fine particle part of ceramsite is called Ceramics. In the ceramsite, there are many fine particles smaller than 5 mm. In the production, a sieving machine is used to screen out these fine particles, which is customarily called ceramsite. Ceramic sand has a slightly higher density and good chemical and thermal stability. Ceramic sand is mainly used to replace natural river sand or mountain sand to prepare lightweight aggregate concrete and lightweight mortar. It can also be used as fine aggregate for acid and heat resistant concrete. The main varieties are clay pottery sand shale pottery sand and fly ash pottery sand. The purpose of using clay sand is also to reduce the weight of the building. Pottery sand can also be used for soilless cultivation and industrial filtration.

Application of Ceramsite

1.Building materials

Ceramsite concrete has been widely used in various types of pre-components and cast-in-place concrete projects in industrial and civil buildings (such as prestressed and non-prestressed, load-bearing structures or enclosures, heat insulation or impermeability, static load or dynamic Contained). Ceramsite can also be used in other construction materials such as pipe insulation, furnace body insulation, cold insulation, sound insulation and sound absorption; it can also be used as soilless bed material and water filtration material in agriculture and gardens.

2.Greening materials

Because the ceramsite has a special structure of porous, light weight and high surface strength, it is used for landscaping and indoor greening to meet the needs of plants for water content, and at the same time meet the requirements of air permeability, especially its characteristics of no dust and light weight. It is increasingly applied to the cultivation of indoor ornamental plants.

3.Industrial filter materials

The active material of ceramsite is also widely used in industry. The biological ceramsite filter material can be used as the biological membrane carrier of the high-load biological filter pond of industrial wastewater, the micro-polluted water source of tap water, the pre-treated biological filter, the coarse-grained material of oily wastewater, the ion exchange resin cushion, and the microorganism Dry storage; suitable for advanced treatment of drinking water, it has the ability to adsorb harmful elements, bacteria, and mineralized water in the water body. It is the filter material with the best active biodegradation effect of harmful substances, and the best biofilm carrier in the biofilter

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China High quality Foam Board Insulation Waterproof Suppliers – 8-16mm ceramic ceramsite for plants – Xinzheng Cheng , The product will supply to all over the world, such as: Ottawa, Sydney, Vietnam, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.