China High quality Chemical Zeolite Manufacturers – industrial perlite ore for foundry manufacturers – Xinzheng Cheng

China High quality Chemical Zeolite Manufacturers – industrial perlite ore for foundry manufacturers – Xinzheng Cheng Detail:

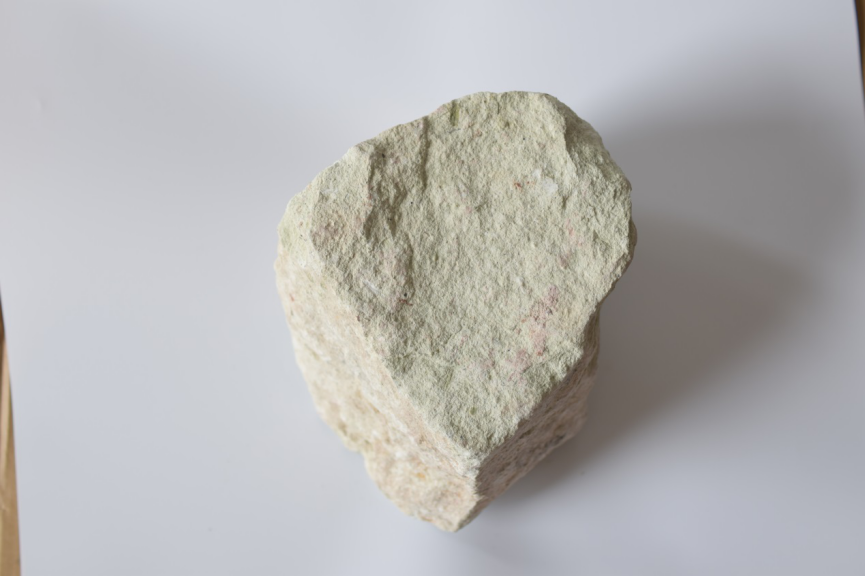

Introduction of perlite ore

Perlite is a kind of volcanic eruption acid lava, vitreous rock formed by rapid cooling. Perlite ore is a raw ore product made by crushing and screening perlite ore. Various specifications of perlite products can be made according to the needs of customers.

Production Process of perlite ore

Raw ore (crushing, drying)→coarse crushing 21mm~40mm(grinding)→medium crushing 5mm(grinding, sieving)→fine crushing 20 mesh~50 mesh (screening)→50~70 mesh~90 mesh~120 mesh ~200 mesh→bagging (grading)

The main physical properties of perlite ore

Color: yellow and white, flesh red, dark green, gray, brown brown, black gray and other colors, of which gray-white-light gray is the main color

Appearance: Ragged fracture, conchoidal, lobed, white streaks

Mohs hardness 5.5~7

Density g/cm3 2.2~2.4

Refractoriness 1300~1380°C

Refractive index 1.483~1.506

Expansion ratio 4~25

General chemical composition of perlite ore (%)

Ore type : SiO2 Al2O3 Fe2O3 CaO K2O Na2O MgO H2O

Perlite : 68~74 ±12 0.5~3.6 0.7~1.0 2~3 4~5 0.3 2.3~6.4

The main industrial indicators of the deposit

The industrial value of perlite raw materials is mainly determined by their expansion ratio and product bulk density after high-temperature roasting.

1. Expansion multiple k0>5~15 times

2. Bulk density≤80kg/m3~200 kg/m3

The main Application of perlite ore

The raw perlite sand is finely pulverized and ultra-finely pulverized, and can be used as a filler in rubber and plastic products, pigments, paints, inks, synthetic glass, heat-insulating bakelite, and some mechanical components and equipment.

Product detail pictures:

Related Product Guide:

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for China High quality Chemical Zeolite Manufacturers – industrial perlite ore for foundry manufacturers – Xinzheng Cheng , The product will supply to all over the world, such as: Australia, Buenos Aires, Netherlands, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to offer you the best service. If you need to have more information, remember to do not hesitate to contact us by E-mail or telephone.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.